The Upgrade Paradox: Why Planned Obsolescence Needs to Yield to Modular Design in the Age of Rapid AI Advancement

Introduction

We live in an era of unprecedented technological acceleration. It feels like just yesterday we were marveling at the capabilities of the latest smartphone, and today, advancements in artificial intelligence are promising to transform our devices in ways we're only just beginning to imagine. Yet, alongside this exciting progress, a persistent and increasingly problematic issue remains: planned obsolescence.

For years, the tech industry has largely operated on a model where devices are designed with a limited lifespan, encouraging users to upgrade by purchasing entirely new products every few years. Whether it's a smartphone that slows down with software updates, a printer whose ink cartridges cost a fortune, or a car with integrated technology that quickly feels outdated, we've become accustomed to a cycle of replacement rather than longevity.

This model, while undeniably profitable for manufacturers, is becoming increasingly unsustainable and out of sync with the pace of innovation, particularly with the rise of sophisticated AI. As AI capabilities are integrated into more devices, the potential for significant functional enhancements through software updates or hardware additions becomes immense. However, the current paradigm of discarding and replacing entire devices creates a significant barrier to realizing this potential.

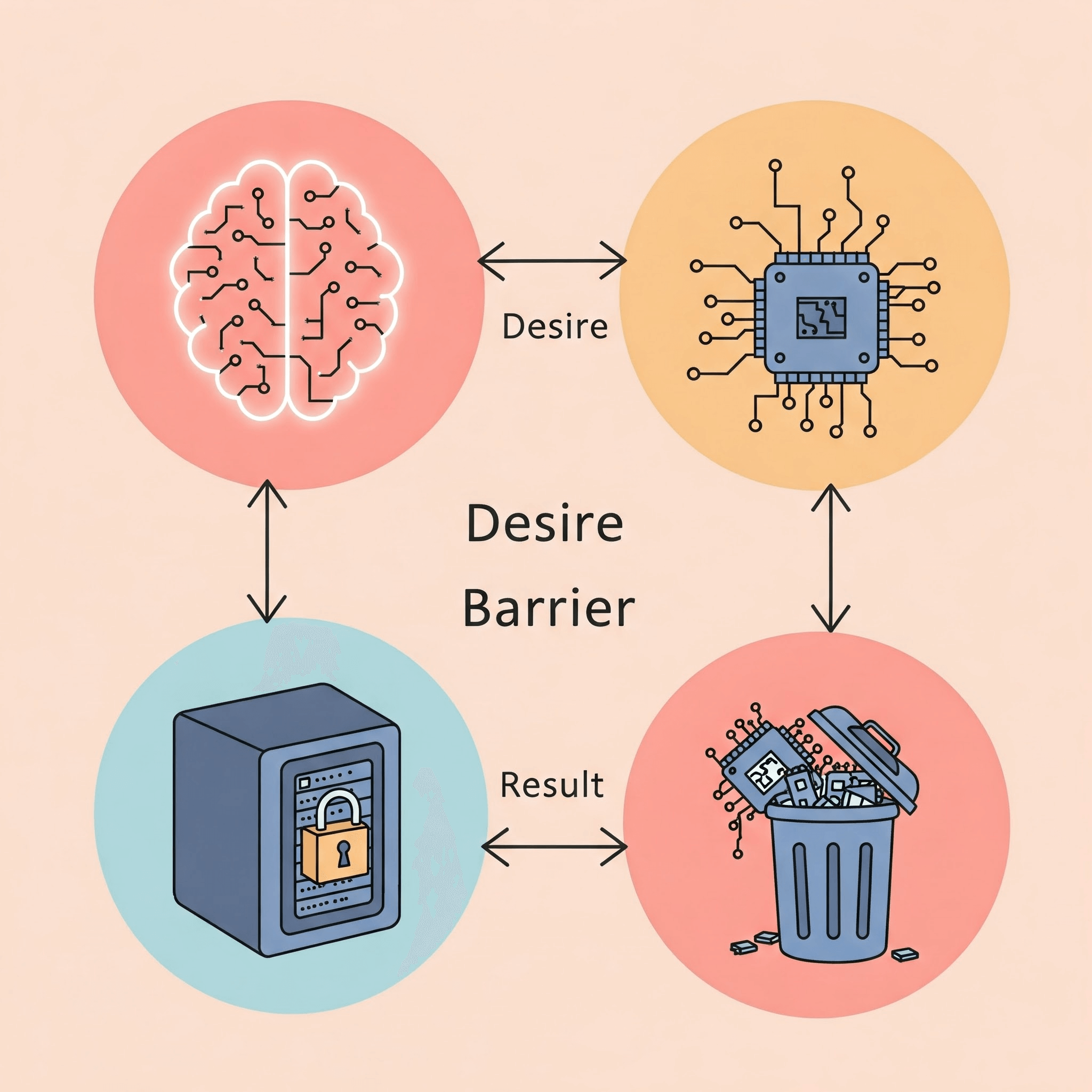

In this article, we'll explore the "upgrade paradox"—the tension between our desire for cutting-edge AI-driven features and a manufacturing model that forces complete replacement—and argue why embracing hardware modularity is the key to breaking this wasteful cycle.

The Problem of Planned Obsolescence

For decades, manufacturers have designed electronics with finite lifespans—an approach that boosts sales but burdens consumers and the planet:

- Performance degradation: Software updates that outpace aging hardware.

- Expensive consumables: Printers that require proprietary, high–cost ink cartridges.

- Outdated integrations: Cars whose sensor or AI hardware can't be upgraded without replacing the entire vehicle.

This "buy–dispose–buy again" cycle is profitable—but environmentally devastating.

This approach, which dates back to the early 20th century, maximizes manufacturer profits by ensuring repeat purchases while externalizing costs onto consumers and the environment. It discourages repair, locks users into proprietary ecosystems, and stifles incremental innovation in upgradeable components.

The Upgrade Paradox

We crave cutting–edge AI features on our devices, yet the existing manufacturing model forces total replacement even when many components still work. The paradox is clear:

- Desire: New AI–driven capabilities (smarter cameras, on–device voice assistants, advanced sensors).

- Barrier: A rigid, monolithic hardware design that can't evolve.

- Result: Excessive electronic waste (e–waste) and unnecessary carbon emissions.

This paradox highlights a fundamental misalignment between consumer aspirations and product lifecycles. We yearn for smarter, faster devices, yet pay the full cost of replacement when just one component becomes outdated.

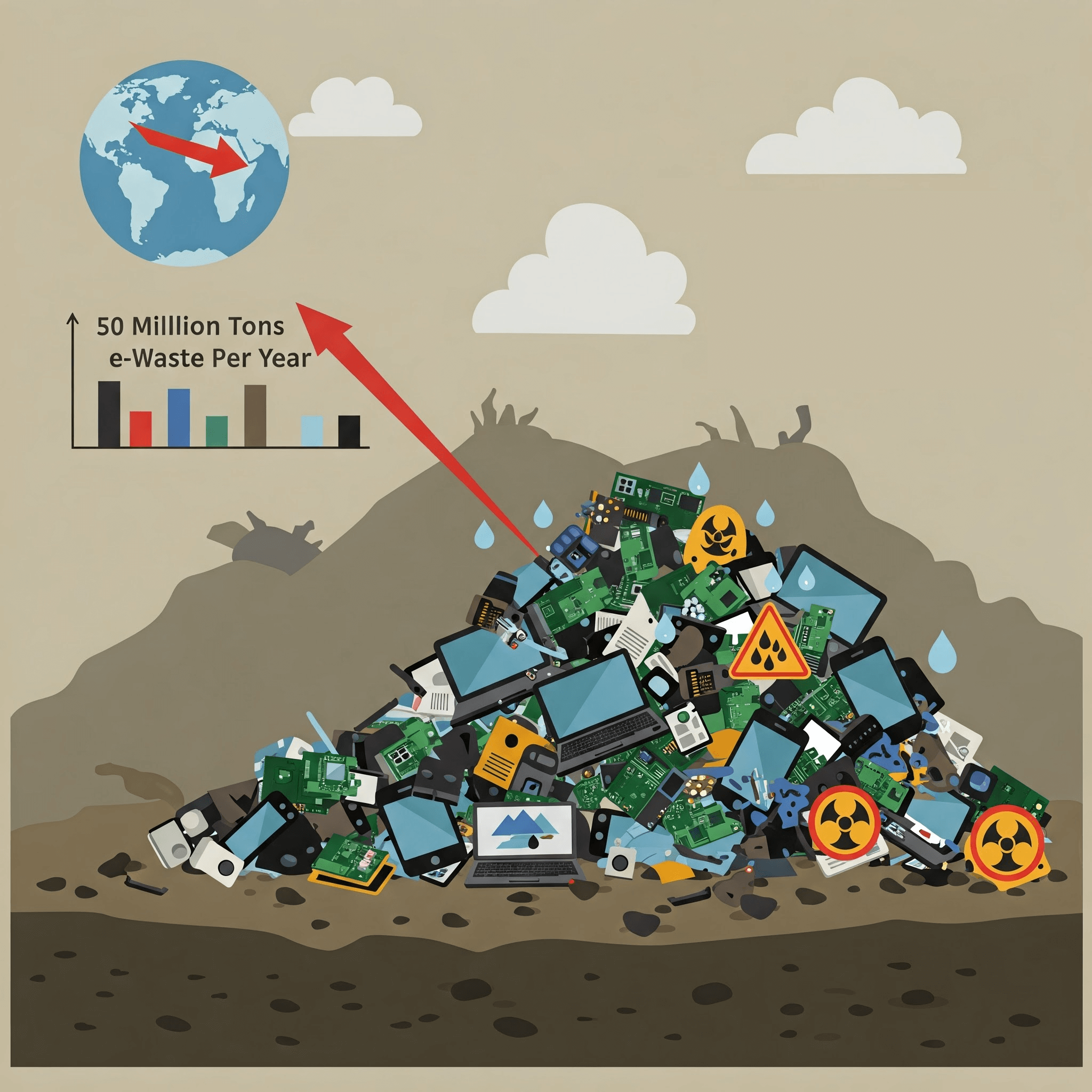

Environmental Impact

- E–waste volume: Millions of tons of discarded electronics end up in landfills every year.

- Toxic leakage: Heavy metals and hazardous materials leach into soil and groundwater.

- Manufacturing footprint: Building new devices from raw materials generates significant energy use and emissions.

The human and environmental toll is significant: e-waste contains toxic substances like lead and mercury, which can contaminate water supplies, while the production of new electronics consumes vast amounts of rare earth metals and energy—driving up global carbon emissions to levels comparable with small nations.

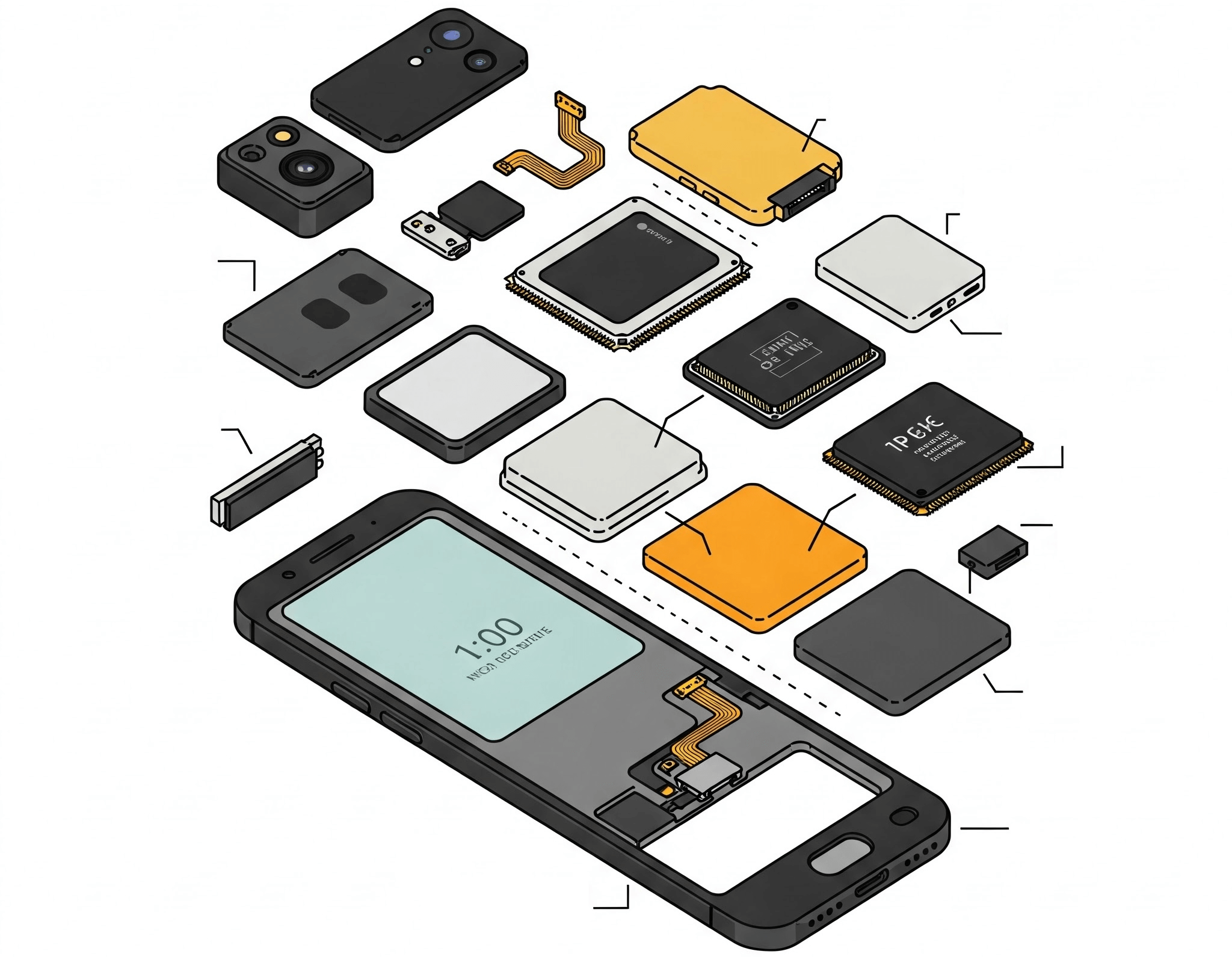

The Promise of Modular Design

Imagine:

- Swapping your smartphone's camera module for the latest sensor.

- Upgrading a laptop's CPU or RAM as new chip generations arrive.

- Refitting your car's autonomous–driving kit without trading in the chassis.

Modularity enables:

- Longevity: Devices live longer through component–level upgrades.

- Savings: Consumers pay only for new functionality, not an entire unit.

- Customization: Tailored tech stacks for individual needs and budgets.

Real-world examples show modularity's potential. Framework laptops allow users to swap CPUs, GPUs, and I/O ports as new technologies emerge, while camera-phone projects like PuzzlePhone demonstrate how a simple lens upgrade can extend device usefulness by years. By separating core computing elements from the housing, manufacturers can foster vibrant ecosystems of third-party modules for specialized use cases.

AI Advancement & Hardware Agnosticism

In Life 3.0, Max Tegmark describes a future where intelligence designs both its software and hardware. Today's AI–powered devices point toward that vision:

- Hardware–agnostic software: AI models that run on any compatible processor.

- Interchangeable AI modules: Plug in a state–of–the–art neural–processing unit (NPU) without changing the motherboard.

This hardware-agnostic mindset is already taking root: standards like USB-C for power delivery and Thunderbolt for data transfer illustrate how modular interfaces can evolve independently of form factors. As AI continues to progress, modular hardware will ensure new AI chips, sensors, and accelerators can be integrated seamlessly—unlocking performance gains without full-device replacement.

Looking forward, this approach will foster competitive markets for module innovators, lower component costs, and stimulate specialized ecosystems for next-generation AI accelerators, image sensors, and connectivity modules.

Benefits for Consumers and Manufacturers

For Consumers

- Lower total cost of ownership

- Freedom to upgrade only what matters

- Enhanced repairability and independent servicing

For consumers, modular devices translate into real savings: instead of buying a brand-new phone for a camera upgrade, you pay only for a new camera module. Enthusiasts can customize their tech stack—game developers might boost CPU speed, while content creators can install higher-end optics.

For Manufacturers

- New revenue streams from upgrade modules

- Standardized component lines, faster time–to–market

- Stronger customer loyalty through sustainable practices

For manufacturers, modularity unlocks ongoing revenue streams akin to software subscriptions—each hardware module becomes a new product line. This model builds brand loyalty, enables faster technology iteration, and reduces supply-chain waste by focusing production on specific modules rather than entire devices.

Real‑World Inspirations

- Fairphone: A modular smartphone championing repairability.

- Google's Project Ara (prototype): Demonstrated the feasibility of swappable modules.

- Right‑to‑Repair legislation: Growing legal momentum for consumer choice and sustainability.

Fairphone (2013–present): This Dutch startup has sold smartphones with replaceable batteries, cameras, and displays—extending device lifespans to 5+ years and reducing e-waste.

Framework Laptop (2021–present): An open-source laptop platform where users can upgrade CPUs, RAM, storage, and I/O ports—demonstrating that full modularity can be both high-performance and consumer-friendly.

Right‑to‑Repair Movement: Governments worldwide (EU, US states like New York and Minnesota) are passing laws requiring manufacturers to provide parts, tools, and documentation—reinforcing modular design as the legal norm.

Challenges and Considerations

While modular design offers substantial benefits, several challenges must be addressed:

- Standardization: Achieving industry-wide agreements on module form factors, interfaces, and electrical standards.

- Economic trade-offs: Balancing the upfront costs of modular enclosures and sockets with long-term savings.

- Design complexity: Ensuring that modular connectors maintain signal integrity and thermal performance.

- Supply-chain coordination: Aligning component manufacturers, OEMs, and third-party module makers to a common roadmap.

Implementation Roadmap

Manufacturers and ecosystem partners can begin embracing modular design through:

- Define open standards for physical connectors, power delivery, and data interfaces.

- Pilot modular prototypes in niche markets (e.g., gaming accessories, industrial sensors) to validate the concept.

- Collaborate with third‑party innovators to build a vibrant marketplace of upgrade modules.

- Educate consumers and service providers on repair, upgrade, and recycling workflows.

- Iterate on feedback to refine module compatibility, user experience, and sustainability metrics.

Conclusion & Call to Action

The upgrade paradox is a relic of slower–moving, closed–system days. In the age of rapid AI evolution and heightened environmental awareness, it's time to champion modularity. Let's urge:

- Manufacturers to embrace hardware–agnostic, upgrade‑friendly designs.

- Policy makers to strengthen right‑to‑repair laws.

- Consumers to support and demand products built to evolve, not expire.

By moving beyond planned obsolescence and toward modular innovation, we can enjoy cutting‑edge AI features, save money, and protect the planet—one upgrade at a time.